Pentacque srl - Industrial plants for water treatment

Industrial plants for water treatment - Via Maestri, 11 - Brescia

Tel. +39 030 3539154 - Fax. +39 030 3542719 - E-Mail: info@pentacquesrl.it

Realization treatment plants

Disoleazione plants and flotation

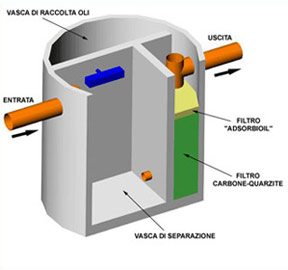

The Pentacque realizes disoleazione water plants. These structures designed for the separation of gasoline, oil, grease and other light fractions derived from petroleum products, the plants at disoleazione are often used as a pretreatment phase of water first before rain or a retention basin, in some cases also added a volume for the retention of solid materials.

Basically there are two types of plant disoleazione: separator gravity separator and the coalescence.

The latter has a package that lamellar increasing effective surface area of flotation supports the aggregation of particles lighter making it easier to lift. This will increase the efficiency of separation was able to reduce the size compared to disoleatori gravity that have larger volumes.

The disoleazione water is obtained by reducing the rate of influenza and preparing an area of calm in which the substances are characterized by a lower specific gravity than water, and go back to draft stationed.

The operation of disoleatori is similar to the principles of sedimentation under the influence of gravity, these behave like sedimentation basins where oil instead of particles settle to the bottom, floated on the surface.

The technology of disoleazione water is normally used as a stage before the chemical to reduce the physical work or in the case of substances with water resistant to sedimentation.

The flotation air or gas is used to separate oil, grease and large quantities of fine particles when the separation by gravity does not reach the desired reaction and it is difficult for high concentrations of pollutants in the water.

The problem of separation due to gravity is very small difference between the specific weight of the water and filling that must be separated and the small size of particles that may need to precipitate a long time.

The solid particles or droplets of oil are being dragged up by gas bubbles and separated at the top of flottatore.

The flotation expected to flow into the entrance accessed from the bottom of the base and exits on the opposite side, floated the material is removed from the surface of the liquid and downloaded.

The development of gas bubbles which carry the solid particles occurs with suction of gas eiettore fed liquid ricircolato (induced gas flotation) or forcing the gas into liquid at high pressure (air flotation or dissolved gases).

Pentacque realizes flottatori vertical cylindrical type with conical bottom. The flottatore is equipped with an air injection system to microbubble and a wiper circular whose task is to remove the floating suspension, the conical base also allows the removal of the sludge settling first.

The type of chemical reagents more likely to be used for the treatment of flotation is tested with laboratory tests. The size of the flotation is performed by Pentacque according to flow and the type of water treated